Understanding SPI Mold Classifications

Welcome to our guide on SPI (Society of Plastics Industry) injection mold classifications – a key framework in the world of injection molding. At Montrose Molders, we prioritize transparency and education, ensuring you make informed decisions for your projects. Let’s delve into the nuances of SPI mold classes, focusing on Class 101, Class 102, Class 103, Class 104, and Class 105.

Understanding SPI Injection Mold Classification:

SPI mold classifications provide a standardized system for communicating the expectations and requirements of molds used in the plastics industry. This classification system helps manufacturers, engineers, and clients align on the intended mold quality and performance.

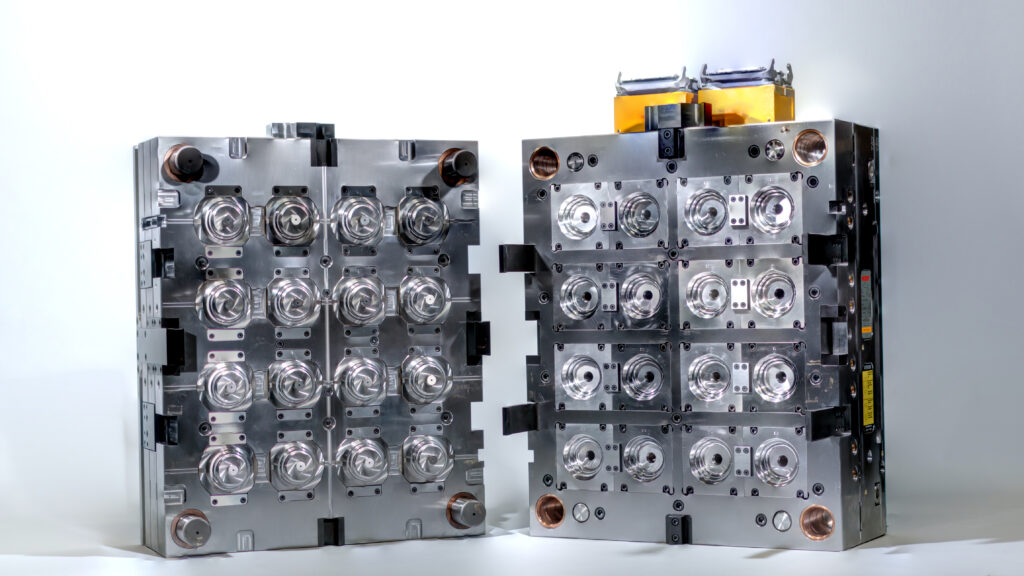

Class 101 Injection Molds: Precision Perfected

Key Features:

– Tightest Tolerances: Class 101 molds are designed for the utmost precision, featuring the tightest tolerances. This makes them ideal for applications demanding micron-level accuracy.

– Extended Lifespan: Crafted for durability, Class 101 molds can withstand high production volumes while maintaining precision. The estimated life of the mold is over 1,000,000 shots.

– Superior Finishes: These molds deliver impeccable surface finishes, meeting the stringent needs of industries like medical devices and electronics.

Ideal For:

– Critical components requiring the highest precision.

– Applications demanding flawless finishes and consistency.

Class 102 Injection Molds: Balancing Precision and Economy

Key Features:

– Good Tolerances: Class 102 molds strike a balance between precision and cost-effectiveness, offering solid tolerances.

– Moderate Lifespan: Designed for medium production volumes, these molds provide durability without the extended lifespan of Class 101 molds. The estimated life of the mold is 500,000 to 1,000,000 shots.

– Versatility: Suitable for applications where high precision is necessary but not as critical as in Class 101 molds.

Ideal For:

– Projects with moderate production volumes.

– Applications where a combination of precision and cost-effectiveness is essential.

Class 103 Injection Molds: Cost-Efficient Solutions for Standard Applications

Key Features:

– Standard Tolerances: Class 103 molds feature standard tolerances, providing a cost-effective solution for less intricate projects.

– Shorter Lifespan: Suited for shorter production runs, these molds offer an economical option without the need for extended durability. The estimated life of the mold is 100,000 500,000 shots.

– Economical Choice: Class 103 molds provide a budget-friendly alternative for projects where ultra-precision is not the primary concern.

Ideal For:

– Projects with lower production volumes.

– Applications where tight tolerances are not critical.

Class 104, Class 105 Injection Molds: Standard and Commercial Options

Key Features:

– Standard Tolerances: Classes 104 and 105 represent molds with standard tolerances, suitable for less intricate or commercial applications.

– Cost-Effective Solutions: These molds provide economical options for projects with standard precision requirements.

– Shorter Lifespan: Designed for shorter production runs without the extended durability of higher-class molds. The estimated life of the mold is 500 to 100,000 shots.

Ideal For:

– General applications with standard precision needs.

– Commercial projects where cost efficiency is a priority.

At Montrose Molders, we specialize in providing mold solutions tailored to your project’s unique requirements. Contact us today to discuss how we can match your needs with the precision and cost-effectiveness offered by our range of SPI mold classifications.