Montrose Molders – Your Custom Plastics Manufacturer

- Home

- Montrose Molders – Your Custom Plastics Manufacturer

Montrose Molders; Your Custom Plastics Manufacturer

Montrose Molders offers two main custom plastics manufacturing services:

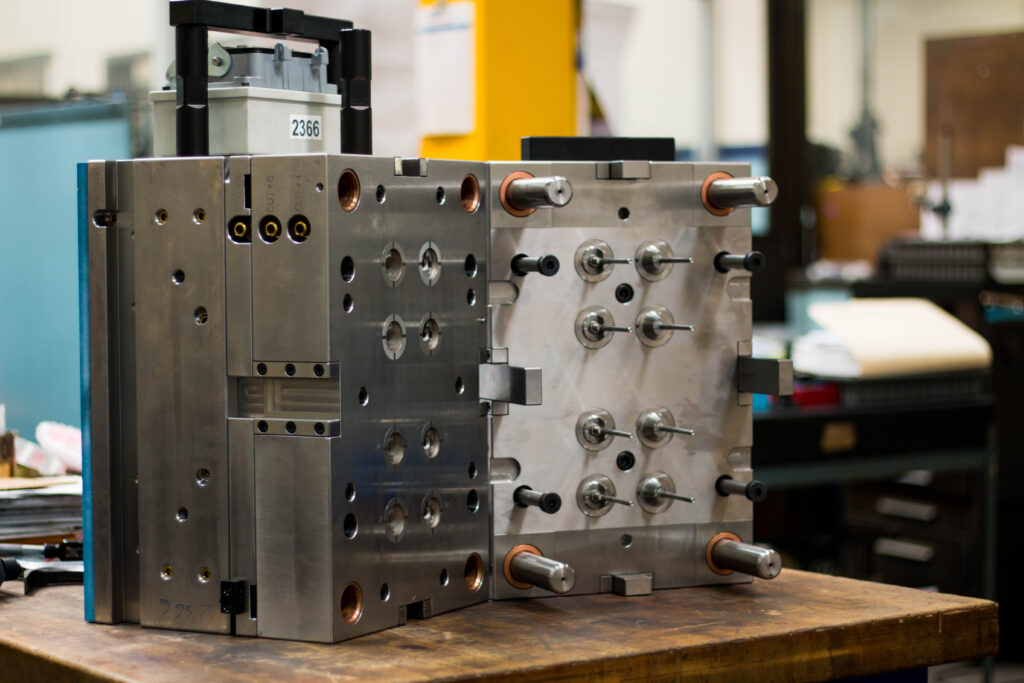

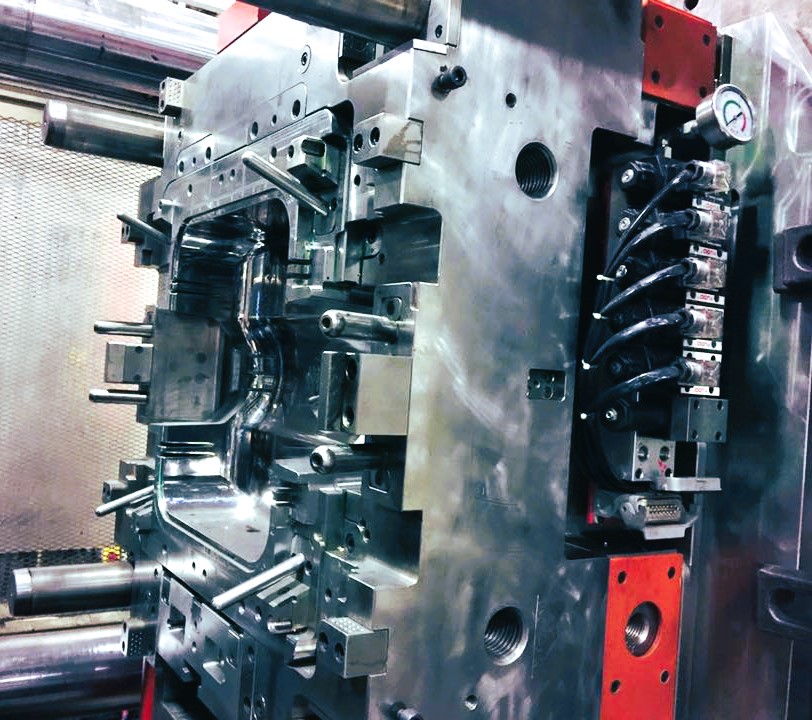

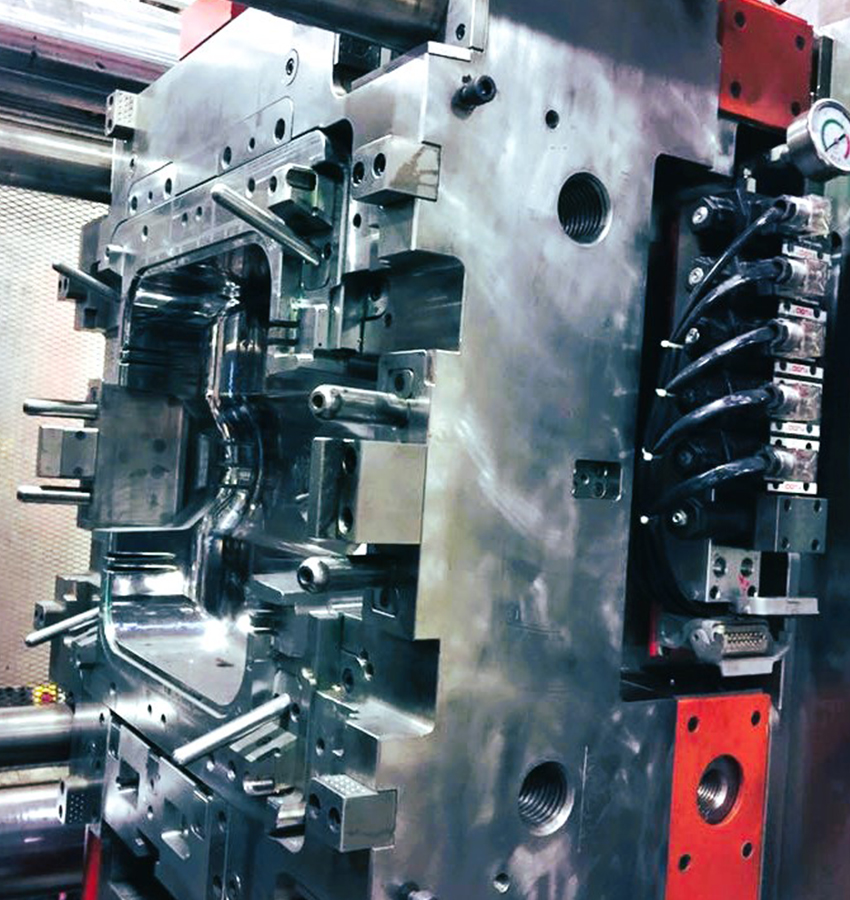

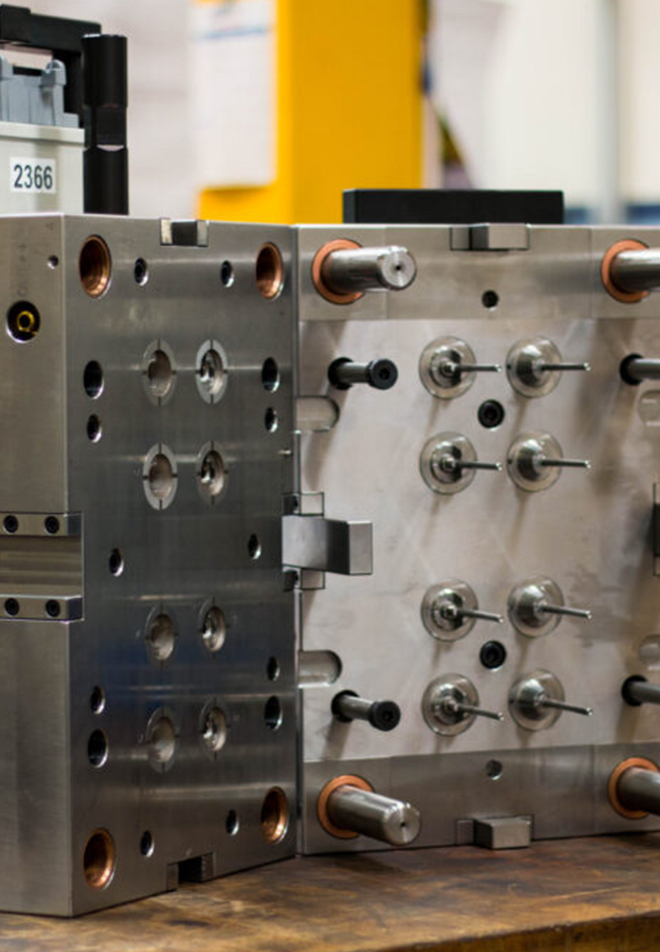

1. Injection Molding

Injection molding is a manufacturing process used to produce a wide range of plastic parts and products. The process involves injecting molten plastic material into a mold cavity, allowing it to cool and solidify, ultimately forming the desired shape. This method is not only fast but also yields precise and complex geometries, making it ideal for the mass production of components with high precision and repeatability.

Click here for more information on Montrose Molders' custom injection molding capabilities.

2. Extrusion:

Like injection molding, is highly customizable and can create components from a wide range of plastic materials. However, it requires a steel die instead of an injection mold. Molten plastics is pushed through the steel die, creating a long continuous shape in the profile of the die. A cutting apartus is then used to cut the part into desired lengths.

What You Need to Get Started with Your Plastics Project

1. Clear Vision: Define your project goals and specifications clearly. Whether it's intricate components through injection molding or continuous profiles via extrusion, a clear vision is the foundation.

2. Material Selection: Understand the characteristics of different plastic materials and choose the one that aligns with your project requirements. The technical experts at Montrose Molders can guide you in selecting the ideal material for your application.

3. Design Files: Provide detailed design files in compatible formats. Whether it's for injection molding or extrusion, accurate design files are crucial for precise manufacturing. If you don't have your idea designed, one of Montrose's industrial designers can help.

4. Quantity Requirements: Determine the quantity of components or products you need. Montrose Molders is equipped to handle both low-volume injection molding and high-volume injection molding production with efficiency.

5. Collaborative Partnership: Partner with a custom plastics manufacturer like Montrose Molders to benefit from our knowledge, technology, and commitment to delivering high-quality plastic products.

Start your plastics project with confidence, precision, and excellence – partner with Montrose Molders for all your plastic manufacturing needs. Reach out today to speak to one of our skilled technical representatives.

Montrose Molders offers two main custom plastics manufacturing services:

1. Injection Molding

Injection molding is a manufacturing process used to produce a wide range of plastic parts and products. The process involves injecting molten plastic material into a mold cavity, allowing it to cool and solidify, ultimately forming the desired shape. This method is not only fast but also yields precise and complex geometries, making it ideal for the mass production of components with high precision and repeatability.

Click here for more information on Montrose Molders’ custom injection molding capabilities.

2. Extrusion:

Like injection molding, is highly customizable and can create components from a wide range of plastic materials. However, it requires a steel die instead of an injection mold. Molten plastics is pushed through the steel die, creating a long continuous shape in the profile of the die. A cutting apartus is then used to cut the part into desired lengths.

What You Need to Get Started with Your Plastics Project

1. Clear Vision: Define your project goals and specifications clearly. Whether it’s intricate components through injection molding or continuous profiles via extrusion, a clear vision is the foundation.

2. Material Selection: Understand the characteristics of different plastic materials and choose the one that aligns with your project requirements. The technical experts at Montrose Molders can guide you in selecting the ideal material for your application.

3. Design Files: Provide detailed design files in compatible formats. Whether it’s for injection molding or extrusion, accurate design files are crucial for precise manufacturing. If you don’t have your idea designed, one of Montrose’s industrial designers can help.

4. Quantity Requirements: Determine the quantity of components or products you need. Montrose Molders is equipped to handle both low-volume injection molding and high-volume injection molding production with efficiency.

5. Collaborative Partnership: Partner with a custom plastics manufacturer like Montrose Molders to benefit from our knowledge, technology, and commitment to delivering high-quality plastic products.

Start your plastics project with confidence, precision, and excellence – partner with Montrose Molders for all your plastic manufacturing needs. Reach out today to speak to one of our skilled technical representatives.