By Brendan Wilson

Plastics waste represents one of the greatest environmental issues we face today. At Montrose, we believe that a transition to recycled and bio-based plastics is the first step towards mitigating the effects of this ever-growing challenge. For this reason, we are positioning ourselves as an organization that can both source sustainable materials reliably and process them into parts expertly.

Once difficult to source and of variable quality, the availability and consistency of sustainable plastics has greatly improved in recent years due to increasing demand on the regulatory and corporate levels.

Sustainable plastics materials can be broken down into five main categories:

· Post Industrial Resin (PIR)

· Post Consumer Resin (PCR)

· Biodegradable and Compostable

· Bio-Reinforced and Bio-Filled

· Ocean-bound

In this blog, we’ll discuss each of these categories and the positives and negatives that you should consider before designing one of these materials into your next project.

Post Industrial Resin (PIR)

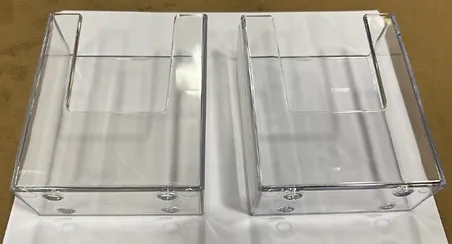

When industrial plastic parts reach the end of their lifecycles, they are brought to a facility where they are cleaned, grounded, and repalletized for reuse. PIR feedstocks are also derived from the waste generated during the manufacture of industrial goods. This type of recycled plastic represents the most widely available and most economical option of all the sustainable materials that will be discussed in this blog.

Historically, PIR was available only in black, but more options for clear and natural materials are hitting the market as more producers are cleaning and sorting waste materials more efficiently prior to reprocessing.

Below is a list of PIR materials available at Montrose:

Post Consumer Resin (PCR)

Like PIR, PCR is produced from discarded plastic parts. Unlike PIR, however, the source is the plastic you bring to the bottom of your driveway on recycling day. Old water bottles, peanut butter jars, and milk jugs are conveyed to a recycling plant, sorted, cleaned, ground, and repalletized for reuse. Because most of this plastic once held perishable food, the cleaning process can be more arduous, rendering contamination more likely.

Below is a list of PCR materials available at Montrose:

Biodegradable and Compostable

Commonly labeled “Bioplastics,” these materials are not traditional hydrocarbon derivatives, but rather produced from renewable sources such as sugar or corn. They represent the most significant innovation in the fight against plastics waste because they break down in the environment under certain conditions.

Below are the main types:

PHA (Polyhydroxyalkanoates) – produced from renewable resources such as sugars and oils. PHA is marine-biodegradable, meaning that the bacteria in the ocean will break it down over time.

PLA (Polylactic Acid) – produced from renewable resources such as corn starch, cassava roots, or sugarcane. PLA is compostable, but not marine-biodegradable.

PolyEarthylene – Plant based bio-resin that mimics olefins like PE and PP

While this category is very exciting and holds much future potential, for now, these materials are very difficult to process efficiently and incredibly energy intensive to produce, leading many to question their carbon footprint. Additionally, bioplastics cannot be introduced to conventional recycling streams because their composition differs from traditional plastics.