In the world of custom injection molding, production volume is a crucial factor that influences various aspects of the process, from the choice of equipment to the overall cost structure. Understanding the distinctions between high-volume and low-volume injection molding is essential for businesses to make informed decisions and optimize their production strategies.

High Volume Injection Molding

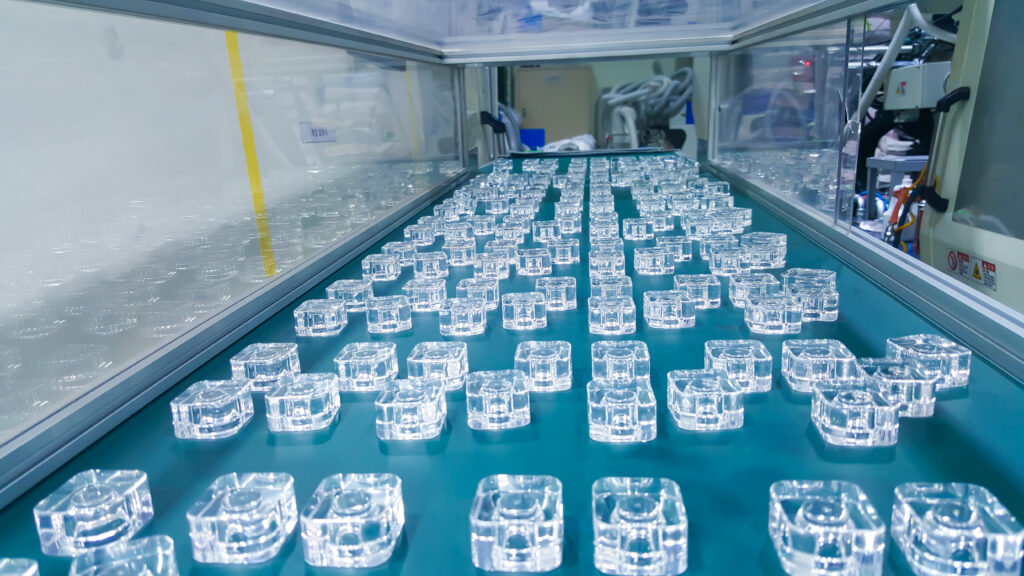

High-volume manufacturing, also known as high-volume production (HVP), is characterized by the production of large quantities of identical or standardized products. This approach is often utilized for mass-produced goods that have a consistent demand, such as toys, electronics, and automotive components.

Key Characteristics of High-Volume Manufacturing:

- Large production volumes: HVP typically involves producing tens of thousands, hundreds of thousands, or even millions of units per year.

- Standardized products: The products being manufactured are often identical or have minimal variations, allowing for streamlined production processes.

- Automated production: HVP heavily relies on automation and specialized equipment to achieve high production rates and consistent quality.

- Economies of scale: HVP benefits from economies of scale, where the cost per unit decreases as production volume increases.

Low Volume Manufacturing

Low-volume manufacturing, also known as low-volume production (LVP), involves producing smaller quantities of products, often with customized designs or specialized features. This approach is commonly used for niche products, prototypes, or goods with limited demand.

Key Characteristics of Low-Volume Manufacturing:

- Smaller production volumes: LVP typically produces smaller quantities, ranging from a few units to several hundred units per year.

- Customized products: Products may have unique designs or specific features, requiring more flexibility in the production process.

- Manual or semi-automated production: LVP often relies on manual labor or semi-automated processes to accommodate the variability of products.

- Focus on quality and flexibility: LVP emphasizes quality control and the ability to adapt to changing product requirements.

Comparing High Volume and Low Volume Manufacturing

| Feature | High Volume Manufacturing | Low Volume Manufacturing |

| Production Volume | Large quantities (tens of thousands or more units per year) | Smaller quantities (a few units to several hundred units per year) |

| Product Standardization | Standardized products with minimal variations | Customized products with unique designs or features |

| Production Automation | Heavily relies on automation and specialized equipment | May involve manual labor or semi-automated processes |

| Cost Structure | Economies of scale lead to lower cost per unit | Higher cost per unit due to smaller production volumes and customization |

| Focus | Efficiency and cost-effectiveness | Quality, flexibility, and responsiveness to customer needs |

| Applications | Mass-produced consumer goods, electronics, automotive components | Niche products, prototypes, customized goods |

Choosing the Right Manufacturing Approach

The choice between high and low-volume manufacturing depends on various factors, including product demand, product specifications, and business objectives. For products with high and consistent demand, HVP offers cost advantages and production efficiency. However, for customized products or those with limited demand, LVP provides the flexibility and adaptability required for small-batch production.

Understanding the distinctions between high-volume and low-volume manufacturing is crucial for businesses to make informed decisions about their production strategies. By carefully evaluating product requirements, demand patterns, and business goals, companies can select the most appropriate manufacturing approach to optimize their operations and achieve their objectives.

Montrose Molders Corp: Your Trusted Partner for High and Low-Volume Manufacturing

At Montrose Molders Corp, we specialize in providing comprehensive injection molding solutions for both high volume and low volume injection molding. Our expertise, coupled with our state-of-the-art facilities, enables us to deliver high-quality products and meet the diverse needs of our customers. Whether you require mass production or customized solutions, we are committed to providing exceptional service and exceeding your expectations.

Contact us today to discuss your specific manufacturing needs and discover how Montrose Molders Corp can be your trusted partner for success.