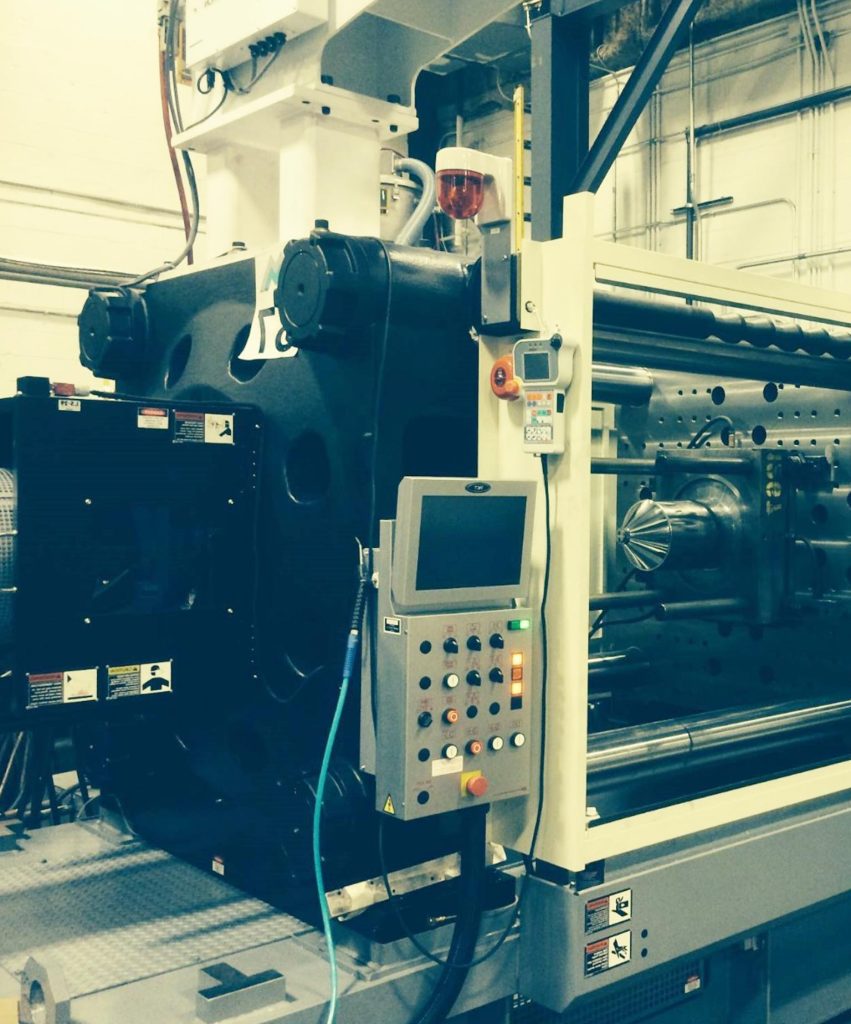

The Importance of Prototyping for Custom Injection Molding Projects

When launching a custom injection molding project, prototyping is a crucial step that is often overlooked. This stage is not just about visualizing an idea, but it’s about bringing it to life, refining it, and ensuring it is viable for mass production. Prototyping offers a tangible way to test and improve product designs, ultimately leading …

The Importance of Prototyping for Custom Injection Molding Projects Read More »