What Should I Look for When Selecting a Molder Manufacturing Company Near Me?

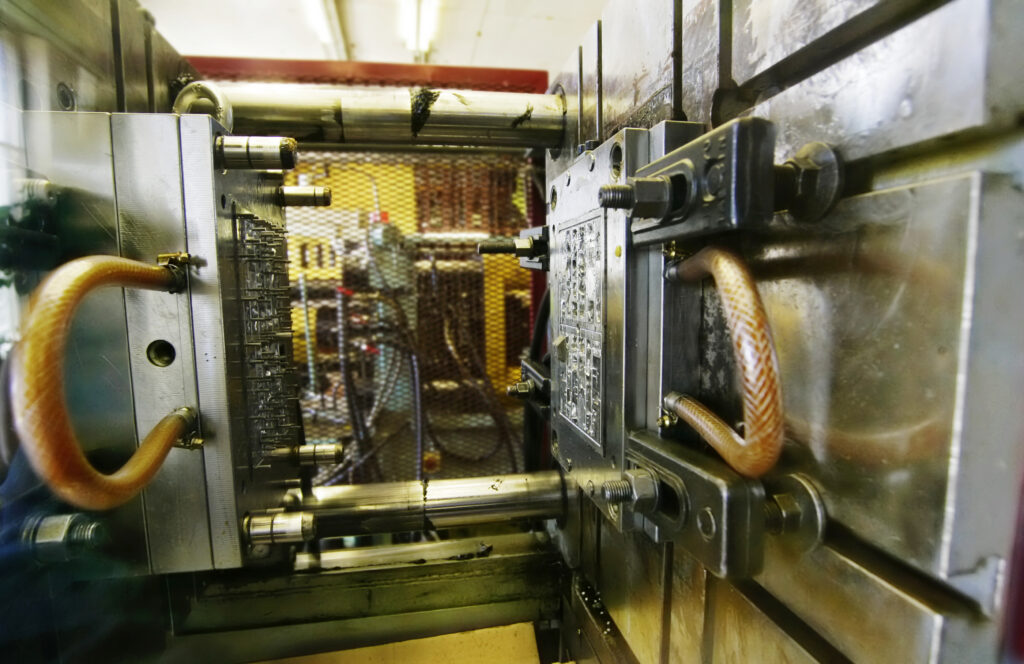

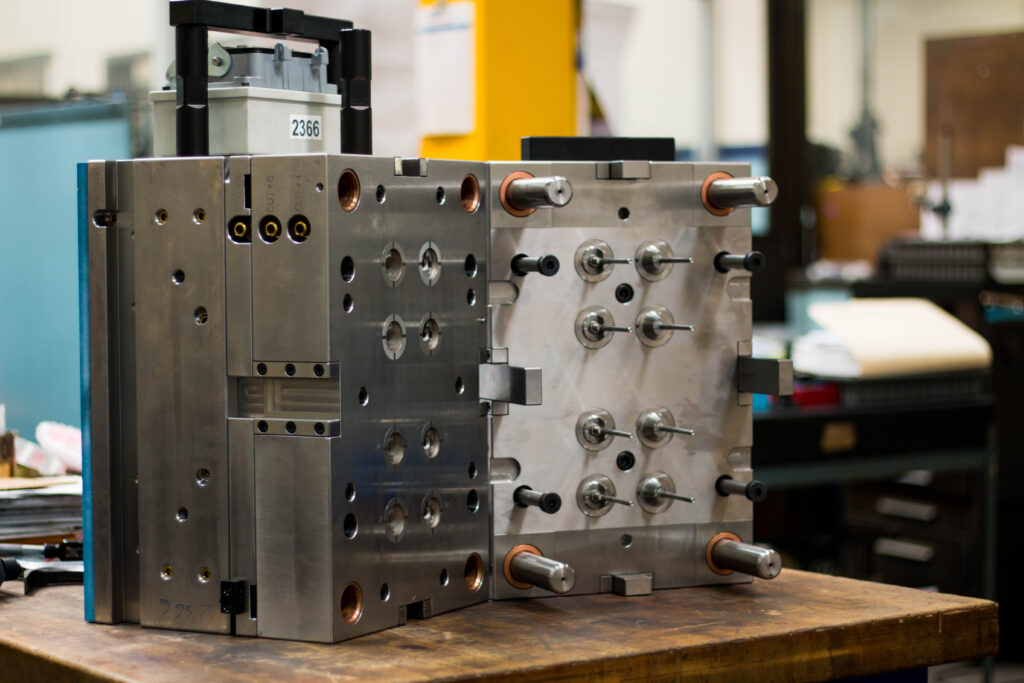

Selecting the right molder manufacturing company is an essential step if you’re looking to create high-quality plastic parts or products. Whether you need custom parts for a prototype or are planning a large-scale production run, the company you choose can make all the difference in your project’s success. If you’re searching for an injection molding …

What Should I Look for When Selecting a Molder Manufacturing Company Near Me? Read More »