In manufacturing, selecting the appropriate technique can make all the difference in reaching accuracy, efficiency, and economy of cost. Injection molding is among the most dependable and flexible methods now in use. Our area of expertise at Montrose Molders is providing excellent injection molding solutions catered to various industrial purposes. We will discuss why injection molding is a preferred choice and how Montrose Molders expert in offering professional answers on this blog.

What is Injection Molding?

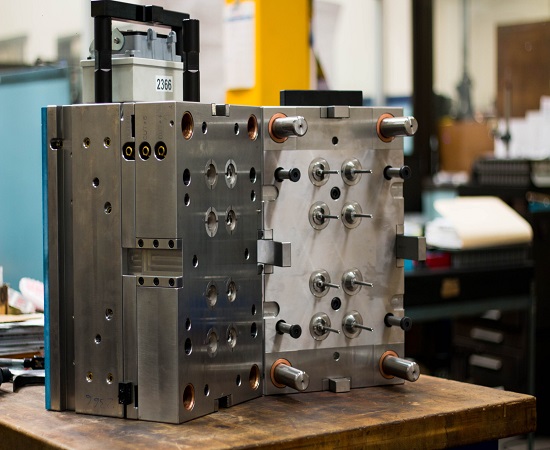

Parts are made via injection molding; a manufacturing technique whereby molten material is injected into a mold. The method starts with heating metal or plastic to a liquid form then injecting it into a perfectly made mold cavity. The mold is removed to expose the finished good once the substance cools and sets. This technique is well-known for generating minimally wasted, high-quality, uniform, and intricate pieces.

Why Choose Injection Molding?

Great Consistency and Precision

For creating complicated and delicate items, precision injection molding NJ provides unmatched consistency and precision. Tight tolerances and great reproducibility made possible by the method guarantee that every component satisfies exact criteria. In sectors including automotive, aerospace, and electronics—where accuracy is absolutely vital—this is especially crucial.

Cost-Effective for Large Volumes

Although mold creation and machinery cause early setup for injection molding to be expensive, for large production runs it becomes quite cost-effective. Once the mold is developed, manufacturing extra pieces is rather cheap, which makes it a reasonably affordable choice for mass production. Over time, the capacity to create thousands of exact parts fast helps to save a lot of money.

Versatility in Material Choices

Among the several materials supported by injection molding are composites, metals, and several polymers. This adaptability lets producers choose components depending on certain needs as strength, flexibility, or temperature resistance. With knowledge of working with several materials, Montrose Molders guarantees that the appropriate decision is taken for the particular requirements of every project.

Minimal Waste and Environmental Impact

Because custom injection molding NJ generates little waste as compared to other manufacturing techniques, one of its main benefits is material economy. Many injected-molded parts are also recyclable, which helps to produce manufacturing sustainably. Consistent with contemporary industry norms and laws, Montrose Molders is dedicated to ecologically responsible methods.

Enhanced Design Flexibility

Complex and sophisticated designs that could be difficult or unattainable with conventional manufacturing techniques are supported by injection molding. Many design engineers appreciate it since it allows one to build intricate elements, such geometric shapes or internal channels, without further assembly. The team at Montrose Molders directly interacts with clients to precisely and quickly realize their creative ideas.

Fast Production and Short Lead Times

One big benefit for producers is injection molding’s speed. Once the mold is developed, fast turnaround times and faster time-to—-market are made possible by speedy manufacturing of parts. In companies where speed is a competitive advantage, this efficiency is absolutely vital. Montrose Molders guarantees prompt delivery of high-quality parts by use of sophisticated technology and simplified procedures.

Montrose Molders’ Expertise in Injection Molding

Being Injection Molder Manufacturer in injection molding, Montrose Molders takes great satisfaction in this. Our staff produces outstanding results by combining modern technology with great experience. We stand apart for this:

- Tailored answers: Every project is different; we are aware of. From material choice to mold design, our staff closely interacts with clients to provide solutions that satisfy particular criteria.

- Modern technology and equipment are investments we make in order to guarantee accuracy and efficiency in every manufacturing run. Our facilities can manage a broad spectrum of production requirements.

- Quality Control: Our first concern in all we do is quality. Every component produced by Montrose Molders satisfies the highest criteria of quality thanks to strict quality control procedures.

- Sustainability Commitment: Our commitment lies in lessening our environmental impact by means of sustainable practices and effective procedures. Our dedication to sustainability conforms with client expectations and industry norms.

Final Thought

Powerful production technique with great accuracy, economy, and adaptability is injection molding. Inject molding is a great option for companies trying to create premium products with less waste and quick turnaround times. Expert solutions provided by Montrose Molders who are leader in Injection Molder USA, address various manufacturing needs by using cutting-edge technologies and industry knowledge.

Montrose Molders is ready to offer the answers you need whether your needs call for complex designs, high volume manufacturing, or environmentally responsible methods. Get in touch right now to see how our injection molding knowledge might improve your manufacturing operations and propel success for your company.