Nearly every day, we hear from companies interested in

learning about ways to improve efficiency, reduce costs, and enhance product

quality. One strategic approach to achieving these goals is through transfer

tooling. But what exactly is transfer tooling, and when should a business

consider it? This guide aims to demystify transfer tooling and provide critical

insights for businesses contemplating this strategic move.

When to Explore Transfer Tooling

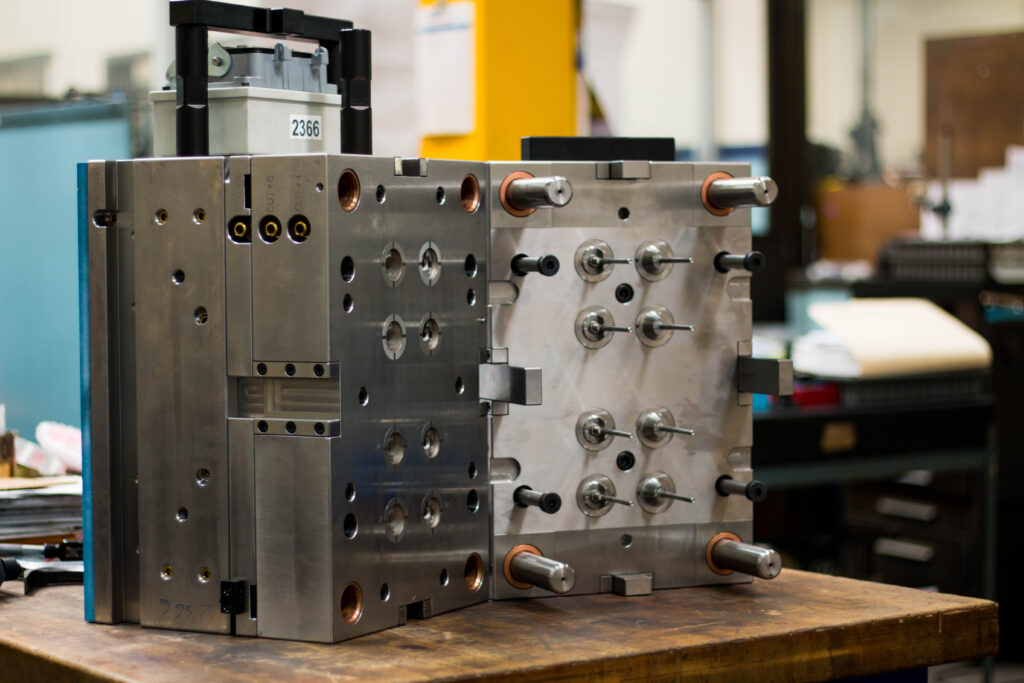

Transfer tooling involves moving existing injection molds

from one production facility to another. This can be driven by several factors:

·

Cost Reduction: Transferring tools to a

facility with lower operational costs can significantly reduce production

expenses.

·

Capacity Issues: If your current molder

cannot meet production demands, transferring tools to a larger or more capable

facility might be necessary.

·

Quality Improvement: Moving to a facility

with advanced technology or higher quality standards can enhance product

quality.

·

Strategic Relocation: Companies might

transfer tools to be closer to their market or supply chain, reducing lead

times and shipping costs.

Requirements for Transfer Tooling

Before initiating a transfer tooling project, it’s crucial

to understand the requirements to ensure a smooth transition:

·

Detailed Tool Records: Comprehensive

documentation of the tool’s design, modifications, maintenance history, and

production records is essential.

·

Tool Condition Assessment: A thorough

evaluation of the tool’s current state, including wear and tear, to estimate

its remaining lifespan and any needed repairs.

Often this is not available, so Montrose can easily handle this

evaluation in our tool shop after the molds arrive.

·

Compatibility Check: Ensure the new

facility’s machines are compatible with the tools in terms of size, tonnage,

and injection capabilities. This is also

something that can be easily verified by a Montrose Technical Rep either before

or after the injection mold has been transferred.

What to Consider When Planning a Transfer Tooling

Project

Planning a transfer tooling project requires careful

consideration of several factors to minimize downtime and ensure a successful

transition:

·

Timing: Schedule the transfer during a

low production period to minimize impact on supply chains.

·

New Molder’s Capabilities: Evaluate the

new molder’s technical capabilities, experience, and quality assurance

processes. A consultation with a

Montrose technical rep can shed light on Montrose’s expensive custom injection

molding and extrusion capabilities.

·

Logistics: Plan the logistics of moving

heavy and sensitive tooling equipment to avoid damage and delays.

·

Legal and Intellectual Property Issues:

Ensure that all legal and IP considerations are addressed, including

non-disclosure agreements (NDAs) and transfer contracts.

Questions to Ask Your New Molder When Planning to

Transfer Tools

To ensure that your new molder is a perfect fit for your

transfer tooling project, consider asking the following questions:

1.

Experience and References: Can you

provide examples of successful transfer tooling projects you’ve completed?

2.

Technical Capabilities: What is the range

of your injection molding machines in terms of tonnage and injection capacity?

3.

Quality Control Processes: How do you

ensure the quality of products produced with transferred tools?

4.

Project Management: How will the transfer

project be managed, and who will be our main point of contact?

5.

Maintenance and Repair Capabilities: How

do you handle tool maintenance and repairs? Are these services done in-house or

outsourced?

6.

Cost Structure: What are the costs

associated with transferring tools to your facility, including any initial

assessment or modification fees?

Transfer tooling can offer significant benefits, including

cost savings, enhanced product quality, and strategic alignment with business

goals. By carefully considering when to explore transfer tooling, understanding

the requirements, planning meticulously, and choosing the right new molder,

businesses can ensure a smooth and successful transition.