Today, we dive into the increasingly critical world of automation in custom injection molding. As the industry evolves, automation is no longer a luxury but a necessity for efficiency, precision, and competitiveness. If you’re considering automation for your injection molding project, here are some essential aspects to keep in mind.

Understanding the Scope of Automation

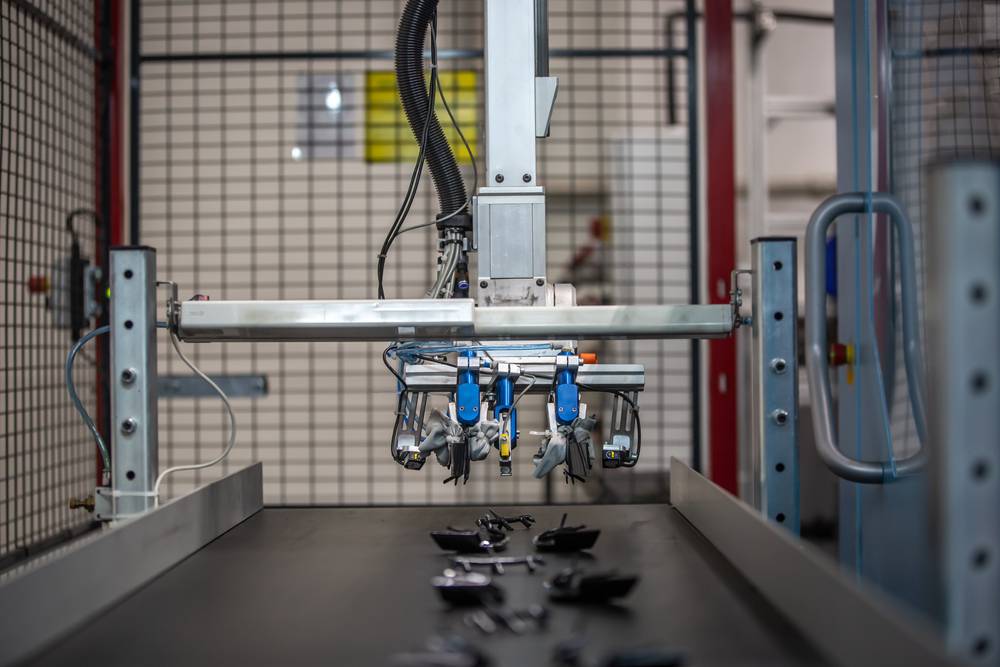

Automation in injection molding isn’t just about robotic arms handling parts. It’s an integrated system encompassing everything from material handling and mold changing to quality control and packaging. Understanding the scope helps in choosing the right level of automation for your project. In some cases, automation can entail a creatively designed robot end-of-arm tool, which can be designed by your custom injection molder. In others, your molder may need to contract with an outside automation company for a more robust solution.

Assessing Cost versus Benefit

While automation involves upfront costs, the long-term benefits often justify the investment. Consider factors like reduced labor costs, increased production speed, consistent quality, and minimal waste. A detailed cost-benefit analysis can help determine the feasibility and ROI of automating your project. One of Montrose’s technical representatives can assist with a cost-benefit analysis, ROI analysis, or payback analysis.

Compatibility with Existing Systems

If you’re integrating automation into an existing setup, it’s crucial to ensure compatibility with current machinery and processes. This includes software compatibility, space considerations, and the ability of your current team to adapt to and manage new technology.

Scale and Flexibility

Ideally, your automation should not only cater to your current needs but also be scalable and flexible enough to adapt to future projects. This foresight will save you from redundant investments and enable you to handle diverse projects with varying complexities and volumes. Examples of this type include versatile 6 axis robots, carton erectors, and conveying equipment.

Quality Control

One of the most significant advantages of automation is the consistency it brings to the production process. Automated quality control systems can detect and correct minute inconsistencies, ensuring a high-quality output consistently. If your project requires a very high degree of repeatability with little tolerance for variation, considering removing the human element with automation.

Training and Technical Support

Implementing automation requires a skilled workforce. Invest in training your team to handle automated systems or consider the support offered by your automation equipment provider. Reliable technical support is crucial for troubleshooting and maintenance...

Conclusion

Automation in custom injection molding is a path toward increased efficiency, quality, and competitiveness. By carefully considering these aspects, you can make informed decisions that align with your project’s goals and your company’s long-term strategy. As your trusted injection molding partner, we’re here to guide you through every step of this exciting journey.

—

Stay tuned to our blog for more insights into the world of injection molding. Whether you’re new to the field or looking to enhance your existing operations, we’re here to help you navigate the complexities of modern injection molding. Speak with one of our technical representatives today for more information.