What is an Injection Mold?

At Montrose Molders, we believe in empowering our clients with knowledge about the processes involved. Let’s explore the fundamental aspects of injection mold.

What is an Injection Mold?

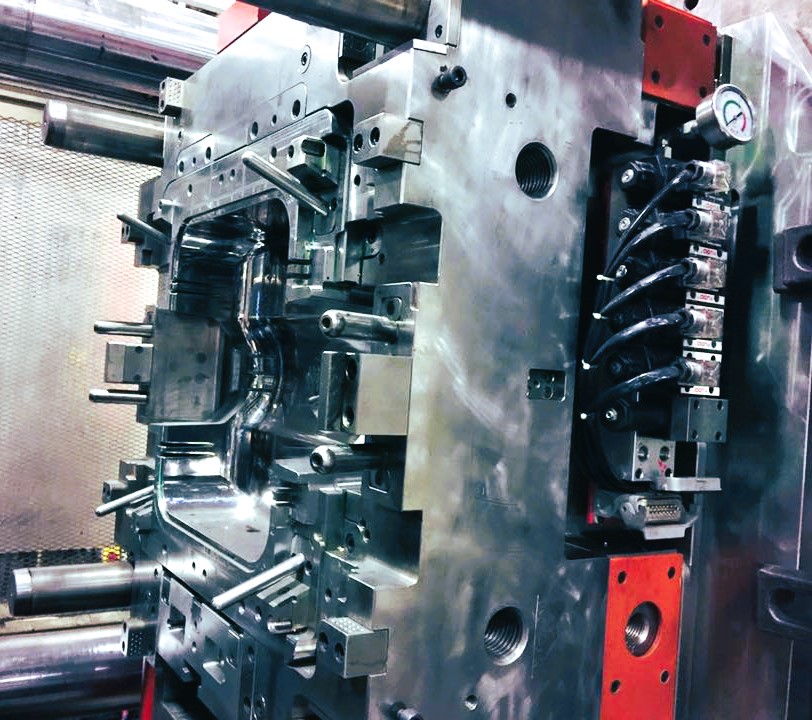

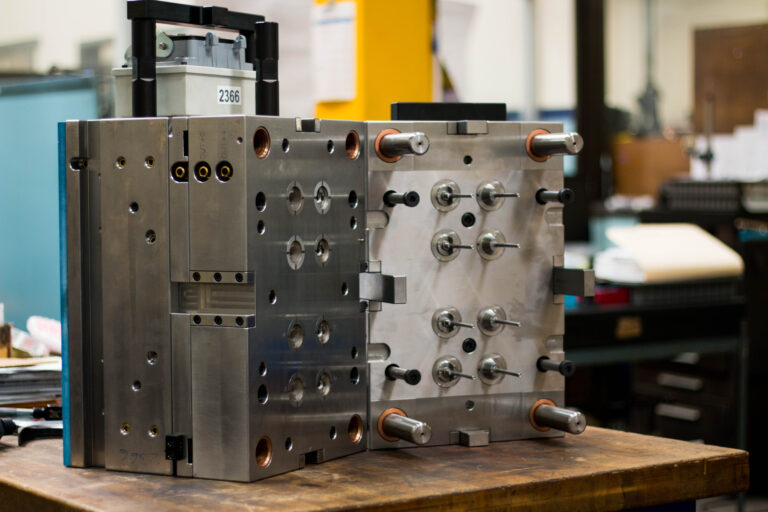

An injection mold is a precision tool used in the injection molding process to shape and form plastic components. This tool is often the first step on the custom plastics manufacturing process, allowing for the efficient and consistent production of intricate and complex parts. The mold consists of two halves—the cavity and the core—that come together to define the shape of the final product.

Parts of an Injection Mold

Understanding the anatomy of an injection mold is key to appreciating its role in the custom plastics manufacturing process. The main components include:

- Cavity: The cavity is the part of the mold that shapes the exterior of the final product.

- Core: The core shapes the interior of the final product and complements the cavity.

- Runner System: This system channels the molten plastic from the injection machine to the mold cavity.

- Ejector System: Once the plastic has solidified, the ejector system pushes the finished product out of the mold.

- Cooling System: Proper cooling is essential for maintaining the quality of the molded parts. The cooling system regulates temperature and ensures uniform solidification.

Why Are Injection Molds So Expensive?

Injection molds can be a significant investment, and several factors contribute to their cost:

- Precision Engineering: The intricate design and precision required in the creation of molds demand advanced engineering expertise.

- High-Quality Materials: Molds are typically made from high-quality, durable materials to withstand the stresses of repeated use.

- Complexity of Design: The more complex the design, the more intricate and expensive the mold will be.

- Tooling and Machining: The precision required in machining and tooling processes adds to the overall cost.

Things to Consider When Purchasing an Injection Mold

When investing in an injection mold, it’s essential to consider various factors:

- Material Compatibility: Ensure the mold is compatible with the materials you intend to use for production.

- Mold Design: Opt for a design that aligns with your product specifications and manufacturing needs.

- Lead Time: Consider the time required for mold fabrication and delivery.

- Manufacturer Reputation: Partner with a reputable manufacturer with a proven track record in delivering high-quality molds.

Why Choose Montrose Molders for Your Injection Mold?

- Expertise: Montrose Molders boasts a team of experts with years of experience in injection molding and mold fabrication.

- Precision: Our commitment to precision engineering ensures that every mold meets the highest standards of quality and accuracy.

- Customization: We understand that each project is unique. Our ability to customize molds allows us to cater to the specific requirements of your products.

- State-of-the-Art Facilities: Our cutting-edge technology and state-of-the-art facilities ensure efficiency and reliability in every project.

- Collaborative Approach: We believe in a collaborative approach, working closely with our clients to understand their needs and delivering molds that exceed expectations.

At Montrose Molders, we don’t just provide molds; we provide solutions. Contact us today to discuss how our expertise in injection molding and mold fabrication can contribute to the success of your project.